It stands to argue that Coca-Cola is one of the multinationals that elicits the strongest love-hate feelings by the public. It is vilified for its influence on global obesity rates and its undue influence on public health policies, causes outrage over the fact that the acidity of its soda dissolves egg shells, and produces accusations of hypocrisy when sponsoring major sporting events – yet, it manufactures one of the most popular drinks worldwide, and people just can’t. stop. drinking it.

It was thus with considerable trepidation that I visited the World of Coca-Cola (museum? “experience”? marketing ploy?) in Atlanta a couple of weeks ago. Would I be paying $16 just for being marketed their syrup-based concoction and the privilege of trying 100 equally sweet and artificial brews from around the world? In short, yes. But the visit also reminded me of a question that had been nagging me for a while – and was compounded by my visits of the most dusty and rural Honduran villages, where without fail a Coca-Cola ad would adorn bus stops, grocery stores or roadside walls:

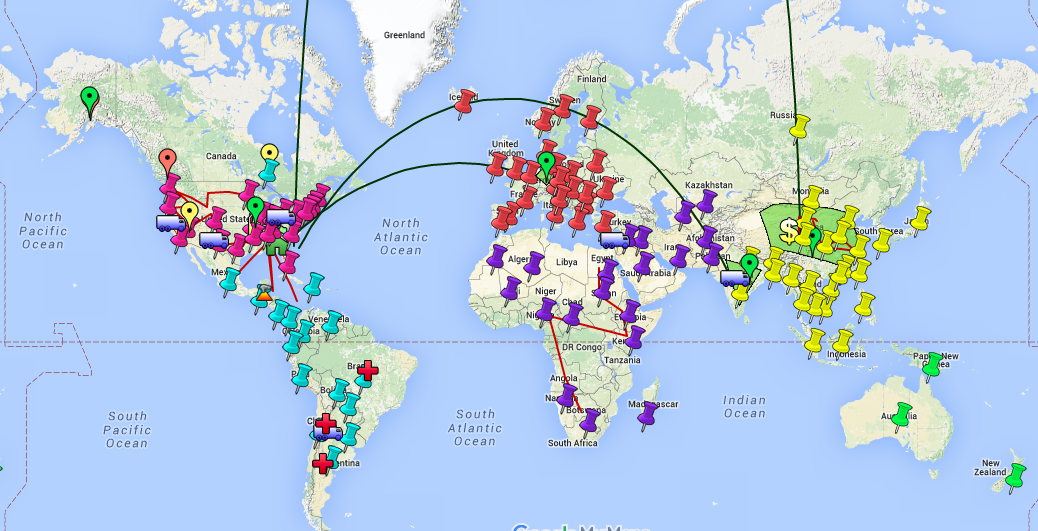

How can Coca-Cola bring their bottles into the last corners of the world, while governments and humanitarian organizations routinely fail at reaching those same places with basic goods and services?

Turns out, I am not the first one to wonder. The whole idea is known as the “last-mile” problem – that is, how can you assure that your products reliably go the last mile all the way to the beneficiary?

What I didn’t understand until I visit the World of Coca-Cola (apart from how many different types of fake-fruit sodas one can possibly sample) is that the Coca-Cola company itself is not responsible for bringing the product all the way to the consumer. Instead, they have bottling agreements with local bottling and distribution partners to whom they sell the syrup and who add local water, sugar and other ingredients, bottle the mixture up and distribute it through their own channels. Thus, local knowledge about the market, infrastructure and the best way to overcome red tape and logistical challenges is a given.

Then, these local distribution partners have developed intricate inventory management systems that track and report back on the location of every crate of coke that leaves the storage unit. Thus, restocking every single partner can be done based on real-time data, rather than estimates and crude models. As many large-scale MNCs, they have also developed sophisticated logistic forecasting tools that allow for a steady distribution flow.

Finally, micro-distribution centers – basically, tiny family-run storage facilities from which Coca-Cola is transported to the final kiosks – create employment opportunities, particularly for women, while ensuring that the last mile is taken care of. The following video also shows the ingenious use of community members and their creativity to transport goods – there is no need for large trucks and paved highways: The stackable, relatively small units can be arranged in a multitude of ways and even put on the back of a bicycle, if need be.

After some reflection, these are some of the first conclusions I arrived at:

I think my initial question was a little naive, in particular regarding the applicability of lessons regarding humanitarian supply chains. It’s important not to conflate development and humanitarian value chains – I believe private companies can provide more lessons for the former since there is a high dependence on existing infrastructure and actor relationships, much of which might be disrupted in disaster situations. Furthermore, the effectiveness of Coca-Cola relies on fine-tuned, repeated interactions that are measured by sophisticated systems – this might also not be possible for humanitarian organizations.

Yet, there are some best-practice-inspired questions any development and humanitarian organization can ask themselves when analyzing their supply chains:

- How close to your most probable target market are you sourcing from? For instance, tarpaulin company Reltex moved its production facility from China to Kenya, in addition to having regional hubs – and, thus, decreased its delivery time from 65 days to just under a week.

- How do you use existing technology? There is now a range of non-technology, mobile and software options to improve humanitarian supply chain visibility and management. Popular software options include Helios and the open-source Sahana Foundation.

- How do you motivate your staff to be performance-oriented? How do you measure performance? In general, for-profit companies have easier quantifiable metrics than multi-stakeholder-oriented NGOs and governments. Is that an advantage?

- How do you engage with community? Can you harness community actors to be your allies?

Indeed, some of this private expertise is being harnessed for public use in the Public-Private-Partnership “Project Last Mile“. In keeping with our conclusions, here Coca-Cola is helping not a humanitarian organization, but government agencies to distribute medical supplies more quickly, reliably and accurately into remote regions. The project is currently taking place in Tanzania, Ghana and Mozambique, with new countries to be added soon.

According to the website, the collaboration between Coca-Cola and local government agencies such as Tanzania’s Medical Stores Department (MSD), the government agency responsible for procuring, storing and delivering medicines throughout the country, have had a significant impact:

- For instance, the MSD expanded its distribution system to include delivery to more than 5,500 health facilities. Previously, MSD delivered to approximately 150 district warehouses, thus losing sight of the last mile.

- The Tanzanian government also reorganized and expanded its warehouses where crucial medicines are properly stored and maintained.

- Geocoded software has helped identify the most efficient delivery schedules and routes from warehouses to clinics, generating significant savings in delivery costs.

- Forecasting accuracy has increased and stock outages of medicine and medical supplies have decreased.

- And stronger human resources models have been implemented, including using clear job descriptions and a performance management system.

- As a result, in some areas where the initiative has been implemented, the availability of critical medicine has increased by 30 percent.

- There are also less obvious knowledge-transfer advantages: for example, in Ghana, Coca-Cola’s refrigeration repair and purchasing programs have modeled improved maintenance systems and routines for the cooler units used to store critical vaccines.

Without a doubt, there are many logistical bottlenecks and planning fallacies that can be alleviated through good management and employee education. In my eyes, however, the main reason why Coca-Cola has this vast delivery network is a simple one: it’s one of the best-known brands with high possible value added. Anybody that agrees to transport or sell Coca-Cola can be sure to turn a profit; this is not necessarily a given for other types of government- or NGO-provided goods.

This got me thinking: Can these lessons still be applied in a ‘lean’ way to development and government organizations? Or is there a possibility to use the pre-existing supply chains and piggyback for non-value adding products? In an insightful blogpost on Project Last Mile, Georgetown alumn Peter Cook reflects that “what I learned is that the project has not entailed any medical products being placed on Coca-Cola trucks. Instead, it is strictly about sharing knowledge of CCK’s management processes with MSD.” But could we also consider leveraging existing, well-working supply chains such as Coca-Cola’s for an equivalent distribution of non-profit products?

The ethical and economic implications are too plentiful to discuss here, but let me close with this:

The real definition of “remote” is relative. It will depend on how much people want to access products, and how inventive they become in accessing them. Is it possible that places are more remote for the public than for the private sector? If so, how do we turn that tide?

As always, I’d love to hear your thoughts!

Title image: via Flickr CC.